anodizing thickness measurement|how to measure anodize thickness : trade The anodizing process parameters have a significant influence on the properties of the oxide formed. If low temperatures and acid concentrations are used, it yields a less porous and harder coating. Higher temperatures and acid content, along with longer immersion . See more 22 de set. de 2022 · Korean Idol Fap: Twice, BlackPink, ITZY, IZONE and other.

{plog:ftitle_list}

Resultado da Maktub Tarot History. Passionate about the study of ancient Egyptian art, painting, sculpture and the specific architecture of the civilization from the .

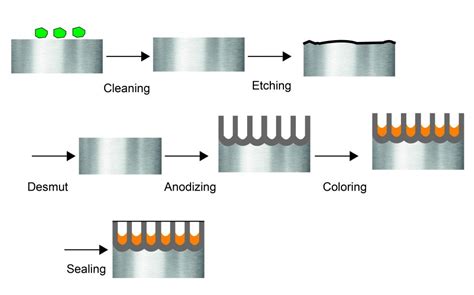

Anodizing is an electrochemical conversion process in existence since the 1930s. Several metals are capable of being anodized including aluminum, magnesium, titanium, and tantalum. Anodized aluminum is used in many applications due to its low cost, aesthetic qualities, and ideal mechanical properties. . See moreThe aluminum part is hung on stripped aluminum or titanium racks ensuring good electrical contact. Throughout the anodizing process, parts are affixed and the racks are suspended in a series of tanks. 1. The aluminum part is dipped in a hot tank containing a . See more

typical anodizing thickness

Anodizing is a highly effective and desirable means of finishing aluminum. Some of the primary advantages of anodizing include: 1. . See more

Anodized products and components are used in thousands of commercial, industrial, and consumer applications: 1. Building products (curtain walls, roofing systems) 2. . See moreThe anodizing process parameters have a significant influence on the properties of the oxide formed. If low temperatures and acid concentrations are used, it yields a less porous and harder coating. Higher temperatures and acid content, along with longer immersion . See moreASTM B244-09(2021) ‒ Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals .

PosiTest magnetic pull-off thickness gage (banana gauge) for the non-destructive measurement of non-magnetic coatings (paint, enamel, galvanizing, metalizing, plating, etc.) on steel. Conforms to ASTM D7091/B499, ISO 2808 .Corrosion resistance is not highly influenced by coating thickness as stated above, sealing is the key concern. However a higher thickness is likely to provide some improvement in corrosion resistance. In this way, for best corrosion resistance, we suggest sulphuric anodising (in excess of 8µm) or hard anodising (up to 60µm).Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in . Discover why measuring plating bath chemistry matters, the different ways to analyze it and the benefits of monitoring it as it happens in real-time. With XRF analysis, you'll gain the knowledge and tools to improve your plating process, thus ensuring top-notch efficiency and quality in surface finishing. . Thickness measurement is made using .

AND METHODS OF MEASURING SURFACE HARDNESS AND THICKNESS OF COATINGS Technical Report TR-#105(Rev.Ø) 19650 Pauling Foothill Ranch, CA 92610-2610 Tel (949) 460-2100 Fax (949) 460-2300 Email: [email protected] www.balseal.com . Plating Thickness And Surface Hardness Measurement A key function to achieving this is accurate plating thickness measurement. The collected data helps determine if the job is running as it should, or if adjustments need to be made to achieve the stated thickness requirements. There are various methods by which plating thicknesses can be measured.

Thickness measurement is a crucial aspect of quality control in anodizing. The thickness of the anodic oxide layer directly influences its protective properties and durability. The most common method for measuring the thickness of anodic coatings is the eddy current NDT method, as specified in ASTM B244.Thickness 0.5µ-7.6µ (microns) Type I B Low voltage chromic acid anodizing (20 volts) Used for 7xxx series alloys. . ** A.Q. - Anodizing Quality - material suitable for architectural anodizing applications . TYPE I "Chromic Acid" Color will vary from clear to dark gray depending on alloy. Copper bearing alloys only yield gray colors. Q. Please refer below details measured using Fisher Dualscope Thickness Measurement: a) Sample without anodizing = 2.5 - 3 micron b) Sample suspected without anodizing= 6.5 micronA coating thickness gauge is an essential quality assurance tool when anodizing, galvanizing and applying zinc coating to metallic surfaces. A coating thickness gauge also is used to measure body paint thickness and uniformity on pre-owned cars, revealing repainted spots, identifying hidden damages and exposing undisclosed accidents .

Anodizing process parameters have a significant influence of the thickness the formed layer. Through various process controls and thickness measurement Anodizers are able to control and correct the anodized coating applications. This is especially important for the thin (Type 1) anodizing. Clear anodized layer thickness can be easily measured .The 6000AN Series Anodizing Coating Thickness Gauge is a versatile, rugged tester using eddy current principles to measure coating thickness on non-ferrous metals, accurately and quickly. Measures Non-Magnetic Coatings (Anodizing, Paint) up 25 mils (0-625 µm) applied to Non-Ferrous metals.

Table 1: Methods for measuring plating film thickness Description Features; Microscope cross-sectional observation methods: A cross section of the sample is sliced, embedded in resin, polished, and etched, and a vertical cross section of the plating is observed using a microscope to determine the coating thickness. The image may be recorded and .

View the most popular topics related to anodizing. . B244-09 – Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and Other Nonconductive Coatings on Nonmagnetic Basis Metals with Eddy-Current Instruments; B680-80 (2004) – Standard Test Method for Seal Quality of Anodic Coatings on Aluminum by Acid .The new Elcometer 456 coating thickness gauge sets new standards measuring the thickness of a coating, helping you to become more efficient. Integral coating thickness gauges are ideal for single handed operation as the wide footprint .AND METHODS OF MEASURING SURFACE HARDNESS AND THICKNESS OF COATINGS Technical Report TR-#105(Rev.Ø) 19650 Pauling Foothill Ranch, CA 92610-2610 Tel (949) 460-2100 Fax (949) 460-2300 Email: [email protected] www.balseal.com . Plating Thickness And Surface Hardness Measurement

METAL PLATING PROCESSES AND METHODS OF MEASURING SURFACE HARDNESS AND THICKNESS OF COATINGS Technical Report TR-#105(Rev.Ø) 19650 Pauling Foothill Ranch, CA 92610-2610 Tel (949) 460-2100 Fax (949) 460-2300 Email: [email protected] www.balseal.com Spinozastraat 1 1018 HD Amsterdam The Netherlands Tel +31 20 638 6523 . ASTM B137: Standard Test Method for Measurement of Coating Mass per Unit Area on Anodically Coated Aluminum. ASTM B244: Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum by Eddy Current. 3.2 ISO Standards. The International Organization for Standardization (ISO) also provides standards for anodizing:

how to measure anodize thickness

XRF coating thickness measurement is a necessity for the billion metal finishing industry. It is also the technology tool that allows contract platers, whose margins are always under pressure, to deliver high quality coatings at lowest cost, knowing they are avoiding the risk of producing below spec, and the cost of wasting valuable material.Measuring plating thickness is an essential part of product development in dozens of industries. PlatingThickness.com – Your source for measuring instruments in plating industry +1 860 683-0781

ISO 1463, Metallic and oxide coatings — Measurement of coating thickness — Microscopical method ISO 2085, Anodizing of aluminium and its alloys — Check for continuity of thin anodic oxidation coatings — Copper sulfate test ISO 2106, Anodizing of aluminium and its alloys — Determination of mass per unit area (surface density) ofCoating thickness measurement, material analysis and microhardness testing in electroplating with Fischer measurement technology. . AN042 Analysis of the metallic content of plating solutions 0.64 MB AN091 Different ways to achieve valid measurement values and optimize measurement performance 0.20 MB AN092 How to choose an XRF instrument 1.29 .

What is Electroless Nickel Plating? Electroless Nickel Phosphorous (ENP) is a nickel-phosphorous alloy (NiP) deposited by a chemical process, unlike the galvanic process of nickel electroplating that requires an electric current. Phosphorous content (%P) ranges from 2%P to 14%P, and specific plating bath formulations produce deposits with low phosphorous (2% .The non-destructive coating thickness measurements can be taken on either magnetic steel surfaces or non-magnetic metal surfaces such as stainless steel or aluminium. Digital coating thickness gauges are ideal to measure coating thickness on metallic substrates. Electromagnetic induction is used for non-magnetic coatings on ferrous substrates .

Measuring plating thickness is an essential part of product development in dozens of industries. Measuring Anodized Plating Thickness – PlatingThickness.com +1 860 683-0781A reversible anvil lets you adapt the gauge to the shape of the object you are measuring. Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat face to measure sheet metal, paper, and other flat stock. Bowman’s L Series XRF (X-ray fluorescence) plating thickness measurement system is a fully enclosed chamber that accommodates samples up to 22″x 24″x 13″. Variable focus camera allows quick measurement of recessed areas. Solid state PIN detector, long-life micro-focus X-ray tube. Unique close proximity of the X-ray tube to the detector .

how to check anodizing thickness

leaf spring load testing machine

spring testing machine manufacturer

spring test main method

Dominação - Acompanhantes em Ji-Paraná - RO

anodizing thickness measurement|how to measure anodize thickness